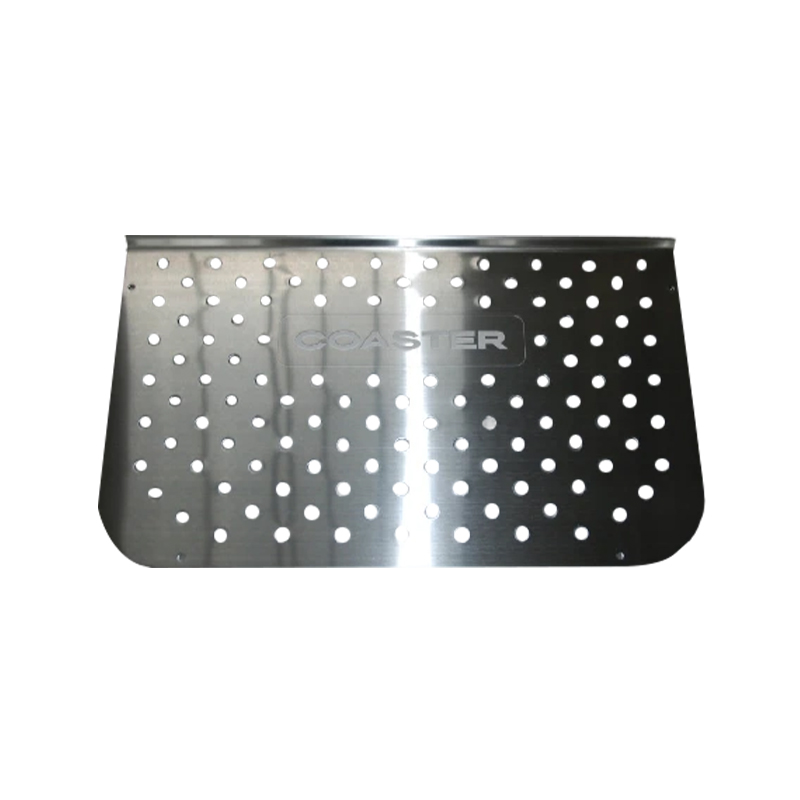

Among the details of a car's interior and exterior, the welcome pedal, though only briefly touched when getting in and out of the vehicle, carries the dual significance of first impression and a sense of ceremony.

- +86-13622252729

- wuxiya01@163.com

- Factory Building No. 6, No. 9-3, Chuangye Road, National High-tech Zone, Zhaoqing City, Guangdong Province